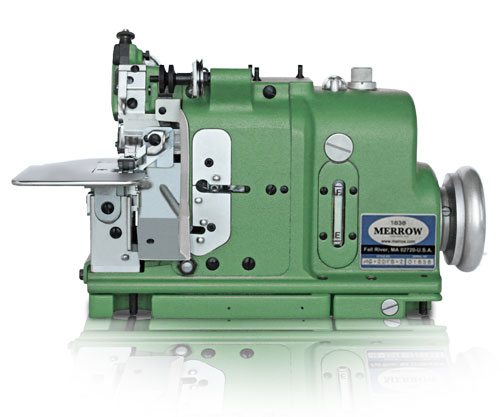

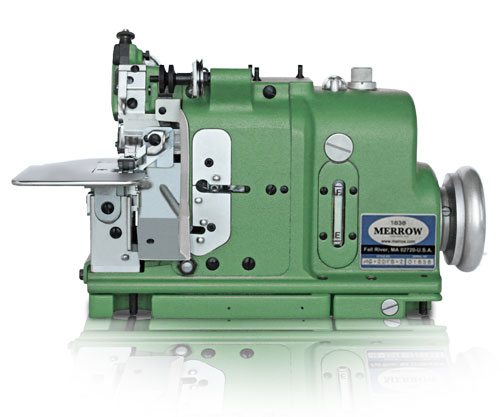

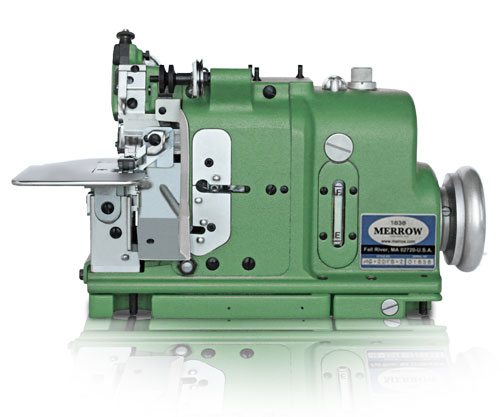

MG-2DFS-2 | FLATLOCK REPLACEMENT SEAM FOR ATHLETIC APPAREL

| |

| OPERATING SPEED |

5500 RPM RPM |

| STITCH WIDTH |

5/32" |

| STITCH RANGE |

1/8"-5/32" |

| STANDARD NEEDLE |

2DF |

| MERROW NEEDLE RANGE |

0SD-5DF |

| FEDERAL STITCH TYPE |

717 |

| MOTOR REQUIRED* |

3450 RPM, 110/220 volt, 1/2HP |

| NUMBER OF THREADS |

2 |

MG-2DFS-2 Applications

The Advantage of the MG-2DFS-2

The MG-2DFS-2 is an advanced sewing machine that was introduced in 2009 to seam today's technical fabrics. It is a two-thread overlock machine that sews a stitch that provides visual distinction and technical performance to athletic garments and active wear.

THE MG-2DFS-2 HAS BEEN REPLACED BY THE MB4DFO (NEW FOR 2011). THE MG-2DFS-2 IS STILL FULLY SUPPORTED AND AVAILABLE FOR CUSTOM ORDERS.

WHY it's better

The MG-2DFS-2 stitch replaces the traditional flatlock stitch. It is narrower, flatter, and more comfortable than the flatlock stitch and is perfect for sewing on today's technical materials. The MG-2DFS-2 stitch width can be varied from 1/8" to 5/32" according to material properties and application requirements.

THE MG-2DFS-2 HAS BEEN REPLACED BY THE MB4DFO (NEW FOR 2011). THE MG-2DFS-2 IS STILL FULLY SUPPORTED AND AVAILABLE FOR CUSTOM ORDERS.

HOW it's better

Before the MG-2DFS-2 is shipped, it is custom configured to sew specifically using customers' unique material and thread. Tension settings, eccentrics, and cutter placement are all adjusted to ensure that the customer receives a unique stitch that is specific to their garment and application.

THE MG-2DFS-2 HAS BEEN REPLACED BY THE MB4DFO (NEW FOR 2011). THE MG-2DFS-2 IS STILL FULLY SUPPORTED AND AVAILABLE FOR CUSTOM ORDERS.

WHERE it's used

The Merrow Flat Seam sewn on the MG-2DFS-2 is ideal for athletic apparel and active wear. Garments with moisture-wicking and insulation properties should be sewn on the MG-2DFS-2, especially those intended as a base layer as the Merrow Panel Seam is extremely comfortable when worn next-to-skin.

THE MG-2DFS-2 HAS BEEN REPLACED BY THE MB4DFO (NEW FOR 2011). THE MG-2DFS-2 IS STILL FULLY SUPPORTED AND AVAILABLE FOR CUSTOM ORDERS.

MG-2DFS-2 Stitches

Get the flash player here: http://www.adobe.com/flashplayer

Merrow Machine Advantages

HERITAGE

Since 1838 Merrow has manufactured the world's best overlock sewing machines. A Merrow Machine is built to sew a more precise stitch and operate longer than any other competitive sewing machine in its class.

Merrow Machines are engineered and manufactured more carefully, designed to last decades, and supported with a network of 156 agents in 65 countries. The Merrow Sewing Machine is The Most PRECISE and TOUGHEST sewing machine manufactured in the world

Overlock stitching was invented by the Merrow Machine Company in 1881. Merrow's original three-thread overedge sewing machine is the forerunner of contemporary overlocking machines. Over time, the Merrow Machine Company pioneered the design of new machines to create a variety of overlock stitches, such as two, and four-thread sergers, the one-thread butted seam, and the cutterless emblem edger. Today Two- and three-thread formations are also known as "merrowing".

In 2010 Merrow Machines are engineered and built in Fall River, MA.

DURABILITY:

Quality of Materials

Our parts and machines are handcrafted and handbuilt

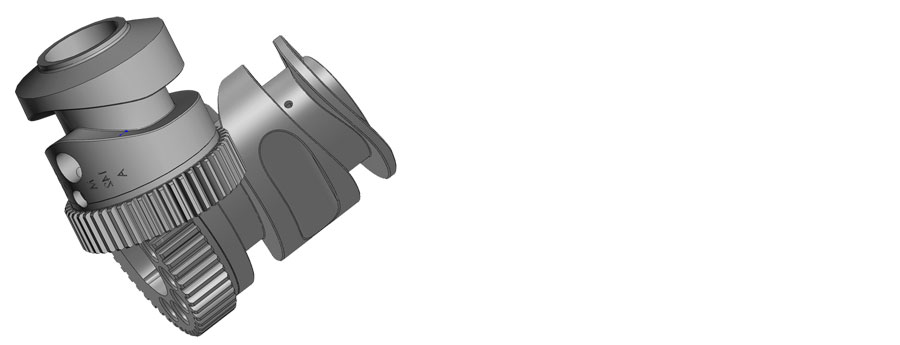

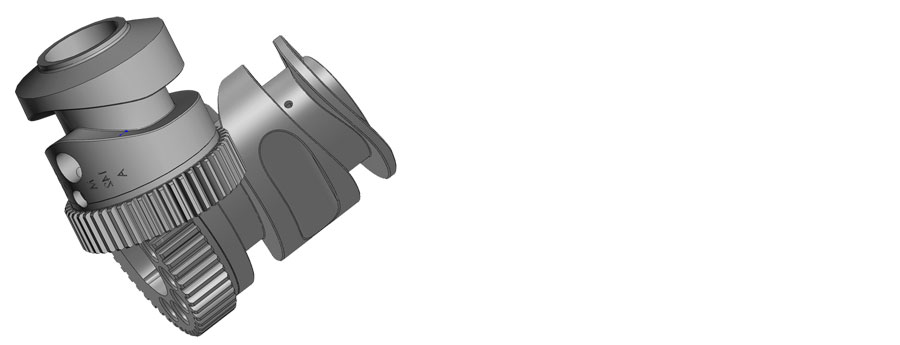

Cams NOT pistons -- Proprietary Cam Technology - Different from all other Sewing Machines

We're the only manufacturer in the world building Cam-driven sewing machines that stand up to heavy use. Merrow's Cam-driven machines produces a superior quality stitch. Using sophisticated 5-axis computerized milling machines, we've succeeded in developing proprietary high-technology components offering faster, quieter, operation and remarkable durability.

Merrow Cams are Machined to Exacting Dimensions Tolerances are held to .001: the tightest in the industry. They have been designed to operate continuously between 2200 and 5500 RPM. Merrow Cams allow a Merrow Machine to create a perfect stitch while ensuring that the sewing machine will last a lifetime.

Special consideration should be paid to the intricacies of Merrow's Cam Technology:

- The Cam groove width and the final surface finish of the Cam groove are created with proprietary manufacturing technology that allows all sides of Merrow's Cam to have an equal, highly polished and uniform steel surface, this results in an approximate coefficient of friction, when lubricated, of .06 or lower.

- Cam gear teeth are cut to a unique specifications with the sides of each tooth shaved to create a proprietary profile. This reduces heat when running.

- Hardness and metallurgy of the Cams are continuously modified, improving the durability of the Cam. The Benchmark for the durability of a Merrow Cam in continuous operation is more than 30 years of operation without failure.

VERSATILITY (for OVERLOCK SEWING):

Sew thousands of different Material Types

Woven Fabric, Knit Fabric, Terry Towel, Denim, Technical Textiles AND Nonwovens. While the machines sew exceptionally on mid-weight woven fabrics, it performs well on a huge number of materials from vulcanized rubber to fiberglass to insulation.

With more than 645 different needle plates and feed dogs, we can modify the sitch to accomodate more demanding fabrics

MERROW Will Build you a CUSTOM MACHINE at NO EXTRA COST

STEP 1: Send us your Material

We will build out a custom machine, at no charge, and sew your material off on the MG-2DFS-2 (or other machine if appropriate). If you would like a video of the process we will provide this along with the sewn sample.

CONTACT MERROW FOR MORE INFORMATION ABOUT CUSTOM STITCH SAMPLES

email: sales@merrow.com

phone: 508.689.4095

fax: 508.689.4098

STEP 2: We will put you in contact with one of our 156 service providers in 65 countries

We will send the completed stitch sample to them, and they will assist you with the purchase and installation of the Merrow MG-2DFS-2

MERROW parts can be Replaced

Availability of Spare Parts

Merrow maintains an inventory of SPARE PARTS for all Merrow Sewing Machines for almost all legacy machines (600 models), ALL Parts are available immediately

Spare Parts QC is Rigorous

You can depend on the parts Merrow provides as all Genuine Parts are machined to very specific tolerances and tested before shipping

Sales, Support and Service

Merrow sells and services all products through a network of sales agents around the world. With 165 agents in 65 countries we are confident that you will find local support. Please feel free to call us directly for product information and stitch samples

SALES

SUPPORT

Local Support in 65 Countries

Contact us directly to find a local agent to setup your Merrow Machine or train your operators

The Best Service Website in the Industry

Enjoy free access to our

support online, our

interactive parts guide and

detailed operation instructions.

SERVICE

Factory Service Program

To make replacing parts and servicing your machine as easy as possible, Merrow has a factory service program with a fixed $299 fee and FREE SHIPPING.

Should your machine need service, we will ship you a box to send us your machine in, replace the needle, loopers, cutters and any other worn parts upon

receipt, and ship it back to you. To learn more, call us at +001 508 689 4095